Fastener

Failure Analysis

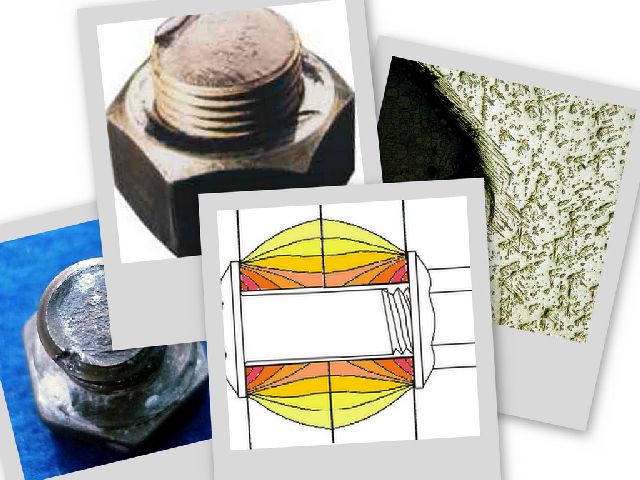

A fastener may

experience either static loading or fatigue loading. Static

loading may be tension, shear, bending, or torsion. These

static loading conditions may occur in combination. One

example of fatigue loading is vibration. In addition to

overload and fatigue, some other common reasons for fastener

failures include environmental issues, manufacturing

discrepancies, and improper use or incorrect installation.

Some common

questions concerning fasteners are listed below:

- How were

the fasteners torqued?

- In what

order were fasteners tightened?

- What is

the best way to verify the torque on fasteners?

- How does

torque value vary over time?

Fatigue is one of

the most common failure modes for threaded fasteners.

Fretting failures may result from small movements between

adjacent surfaces. Additionally, atmospheric corrosion,

liquid immersion corrosion, galvanic corrosion, crevice

corrosion, stress corrosion cracking, and hydrogen damage

may contribute to fastener failure.

Material

selection, heat treatment, cutting or rolling threads,

manufacturing, assembly, and design are some of the factors

that effect fastener failures. Failure analysis can

determine the cause of the fastener failure and determine

the primary or contributing causes of fastener failure.